Building a Better BIM with Laser Scanning

For the past decade, KHS&S has used Building Information Modeling (BIM) – the creation of a 3-D digital representation of our work scopes – to improve construction accuracy and reduce unknown project variables. But until recently, adapting these models to the project environment or existing structures on a job site, was still wrought with potential challenges and uncertainties. Fortunately, laser scanning – a relatively new technology – is helping change that and has already proven beneficial on one of KHS&S’ large, themed attraction projects.

In the simplest of terms, 3D laser scanning is similar to taking an exceptionally accurate, 360-degree photo of a project area or complete job site. In reality, it’s much more technical. And its benefits are much more robust.

“Essentially, the amount of data collected during a typical 3D laser scan creates a complete digital representation of a project,” said Andrew Vargo, project manager, KHS&S-Orlando. “That’s an effective method to capture real-time information and deliver practical cost-saving applications KHS&S is known for.”

In laser scanning, invisible laser beams scan billions of points within a structure in record time. The beams bounce off the surfaces of targeted objects such as walls, ductwork and steel piping, to capture a “point” of data. More than one million unique points are captured every second with up to 300 million points gathered during just a five-minute scan. The collection of huge numbers of these individual data points create a “point cloud,” which is a real-time, digital reality capture of a 3D shape or feature.

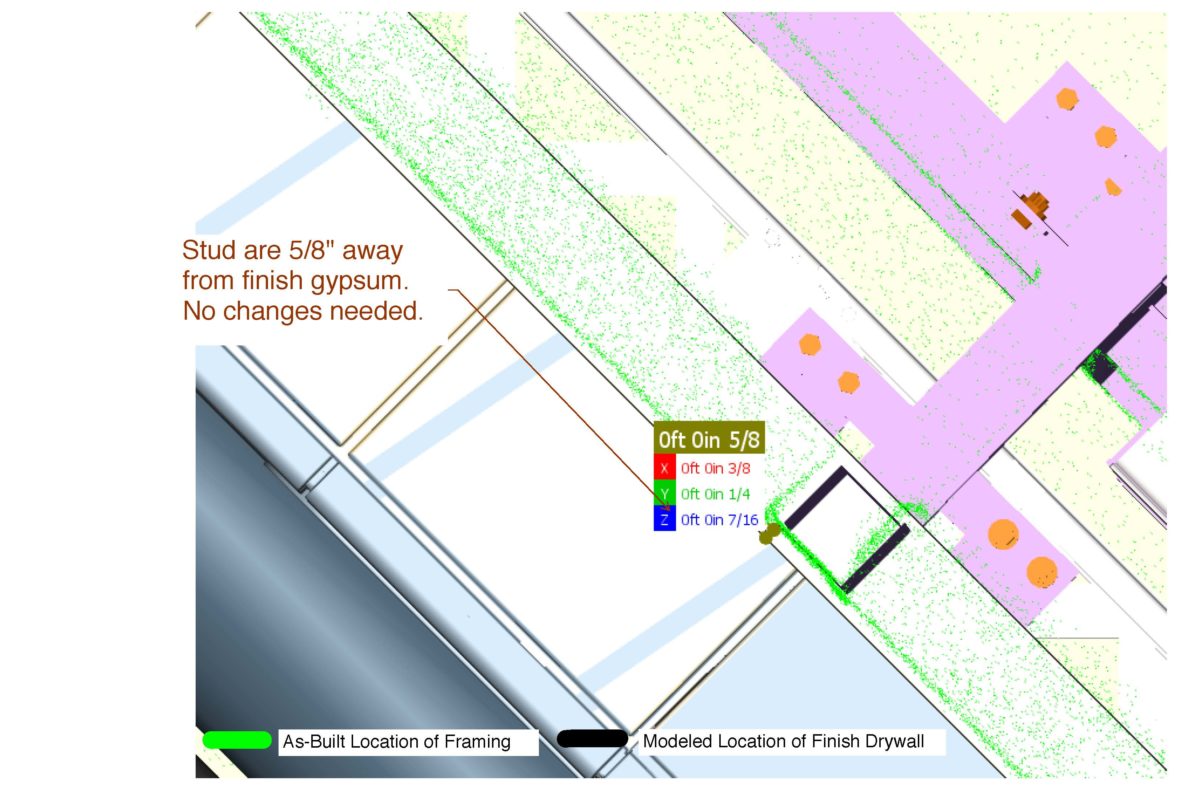

By uploading point clouds into KHS&S’ BIM, KHS&S preconstruction and BIM experts have the ability to not only visualize its own work product, but also the exact environment or structure in which the work will be installed.

As a result of combining laser scanning with BIM, KHS&S professionals can better identify potential problems and develop practical time and cost-saving applications and strategies.

“The 3D scanning model allows us to zoom in, spin it around, look at the point cloud structure from every angle possible, and we use that information to build the 3D BIM models,” explains Daniel Han, KHS&S design phase coordinator. “We update the computer model with new data points taken of the project, and compare that to the work happening in the field against the 3D model and avert any potential for mistakes before the work continues.”

General contractors or project owners use their 3D scanner and provide KHS&S with the data points. “GCs like using this technology, because it’s efficient, saves time, money and helps keep the project on schedule,” said Han.

On a recent Central Florida themed attraction job site, Scott Little, project superintendent, KHS&S-Orlando, saw firsthand the measurable benefits for both the owner and KHS&S. In the early framing stages of a complex themed environment, KHS&S first followed the digital blueprints to determine wall and ceiling placement. Craftsmen began work on the walls and ceilings, and after a good portion of the framing was complete, but well before hanging drywall, the owner had the entire room scanned with 3D equipment.

The work involved a very complex 80-foot soffit that ran the length of the ceiling and 40-foot-high walls with multiple components running at different angles. The scan revealed the soffit wasn’t quite matching the digital blueprint, so KHS&S reframed the soffit in about a week. If not corrected, the work that followed would have been affected, delaying the project, including installation of themed show pieces, by a couple of weeks.

“Not only is the checking and cross-checking important to the accuracy of the finished product, but the craftsmen take a lot of pride and put their heart and soul into their job, so having to tear down any of the work is tough,” Little said.

The rework on this job was minimized, since the scan was able to detect even a slight degree of irregularity out of tolerance (which isn’t unusual on projects of this scale). Thanks to the 3D scanning, a teardown was averted. Making adjustments very early versus catching an irregularity long after the work has progressed kept the job closer to the schedule and budget.

A system of checks and rechecks of the themed environment that compared the scanned point cloud to the digital blueprint continued until the work was complete. The scan validated the field work and gave the project owner confidence the job was moving ahead as planned.

“The 3D scanning is also great for having information at our fingertips in a construction coordination meeting as we’re comparing the scan with the work to date,” said D.J. Smith, KHS&S Lean champion. “We can pull up the scan on the computer and see exactly what the current field conditions are, such as where the duct work is, where the studs are, and see any clashes where duct work might need to be rerouted, for example.”

The high-tech laser scanning removes a large degree of human error from the surveying process and enables significantly higher volumes of data to be collected over a considerably shorter period. The result drives more reliable, measurable outcomes and benefits the overall project team.

“This was a valuable lesson learned,” said Jess Robinson, KHS&S vice president. “As laser scanning becomes more prevalent in our industry, we anticipate applying it in early stages of the QC process when critical and/or complex dimensioning can greatly impact follow-on work.”

“With our high standards,” Vargo adds, “we want to make sure every step of construction is precise, and 3D scanning with BIM can certainly help us achieve that goal.”